Electronically Controlled Engine Maintenance

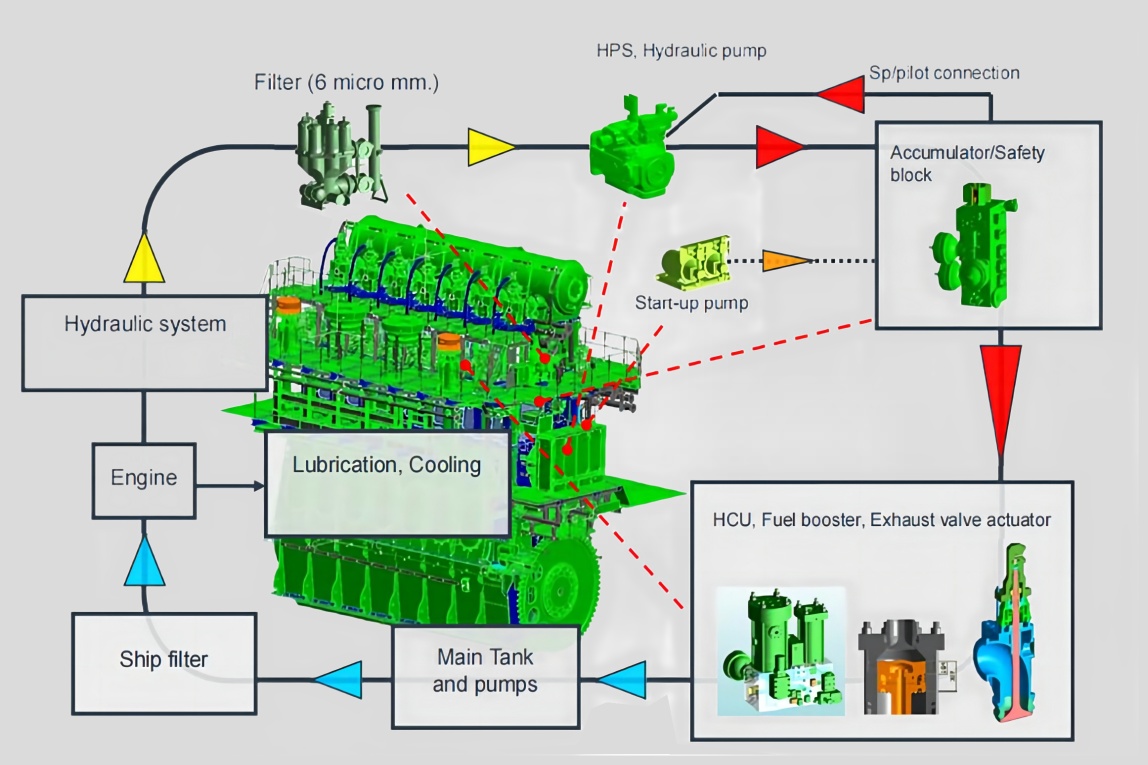

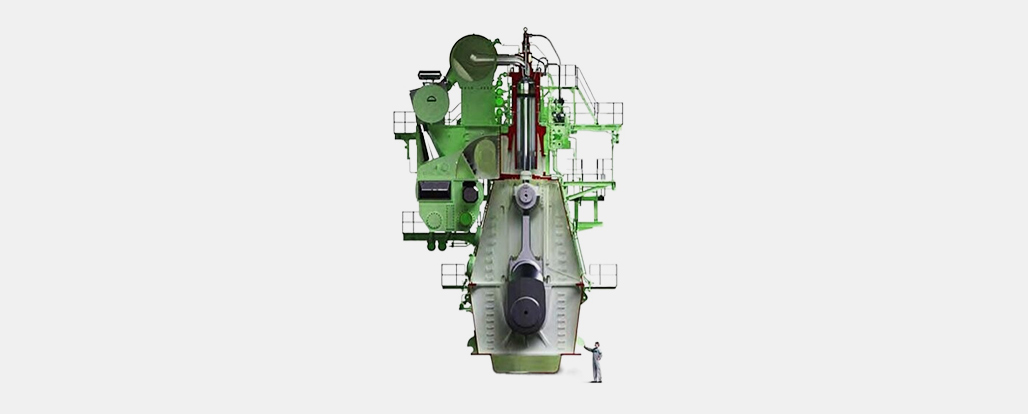

Electronically Controlled Engine runs for 5 years, according to the suggestion of the diesel engine manufacturer, the hydraulic parts of the ME should be sent to the workshop for overhauling and calibration. Other equipment needs to be replaced with genuine spare parts on board, and the electronic control system needs to be checked and maintained.

Fuel booster

32,000 R/H

exh. valve actuator

32,000 R/H

Accumulator

32,000 R/H

FIVA valve

32,000 R/H

Cylinder lubricator

32,000 R/H

Distributor block

32,000 R/H

Accumulator block

32,000 R/H

Hydraulic hose

32,000 R/H

Accumulator

32,000 R/H

Compensator

32,000 R/H

Electric control panel

32,000 R/H

MPC

32,000 R/H

Level switch

32,000 R/H

ETC.

32,000 R/H

Pneumatic system

32,000 R/H

Chain re-tighten

4,000 R/H

Chain tightener

4,000 R/H

Guide bar

4,000 R/H

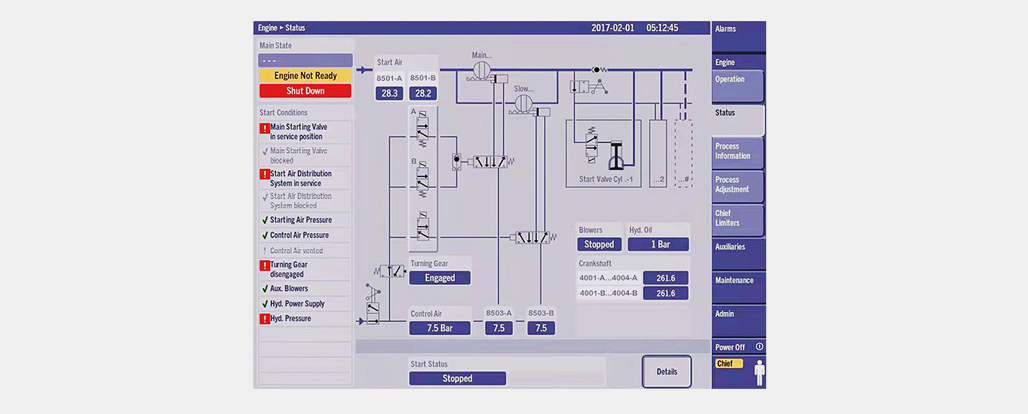

1) Calibration for inductive sensor

2) Calibration for swash plate positioner

3) Calibration for exhaust bypass system

4) Calibration for telegraph handle

5) Function test for tacho system

6) Function test for safety device